Slab jacking is also known as concrete slab lifting or concrete jacking. It’s a cost-effective and efficient method to lift and stabilise sunken concrete slabs. The process involves injecting a mixture, often made from a combination of water, soil, sand, and cement, beneath the slab to raise it back to its original level. This procedure not only rectifies the immediate problem but also addresses the underlying issue causing the slab to sink in the first place.

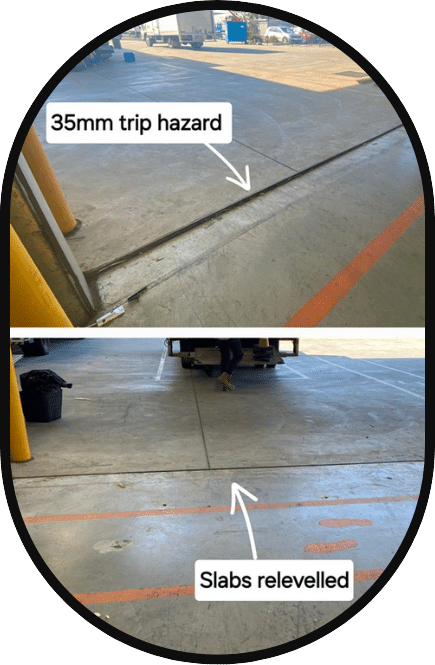

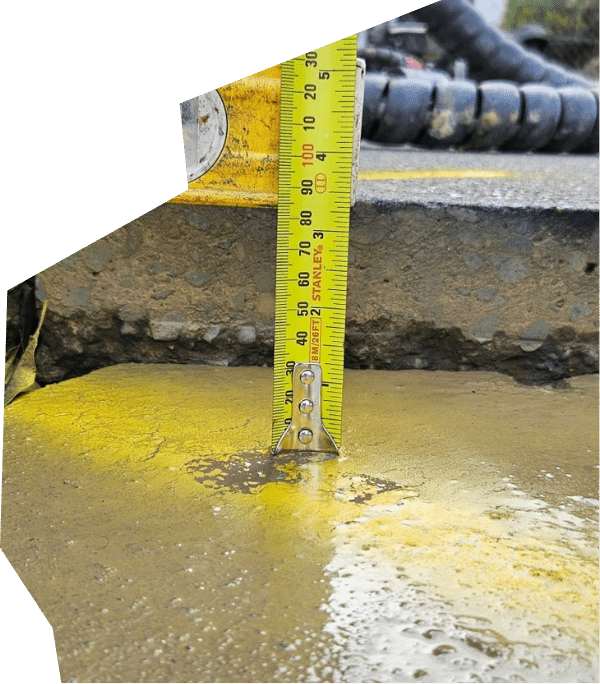

Slab jacking is typically used when the soil underneath a concrete slab compacts or washes away, creating a void. The weight of the slab, combined with the effects of gravity, causes the unsupported slab to sink or tilt, leading to uneven surfaces.

Through slab jacking, we fill these voids, reestablishing support to the slab and lifting it back to its intended position. This technique is widely recognised for its effectiveness, affordability, and minimal disruption compared to traditional methods like slab replacement.

How Does Slab Jacking Work?

The slab jacking process begins by drilling small holes into the sunken concrete slab. Then, a specialised mixture or slab jacking foam, such as polyurethane slab jacking material, is pumped under the slab. As the mixture fills the void, it pushes the slab upwards, lifting it back to its original position. This method is often used for levelling a concrete slab that has become uneven due to soil movement or erosion.