Specialty grout is made up of a mixture of materials. These provide chemical resistance as well as waterproofing. There is a range of different specialised grouting services. For example, any type of grouting undertaken in a mine is considered a specialist, whether stabilising or infilling.

Compensation grouting helps reduce the damage caused by settlement after excavation. Your grouting contracts inject small amounts of epoxy grouting between the structural foundations of the excavation. In compaction grouting, cement grout is injected directly into the ground to strengthen voided, loose material. It’s a stiff grout that can be used in natural and manmade situations.

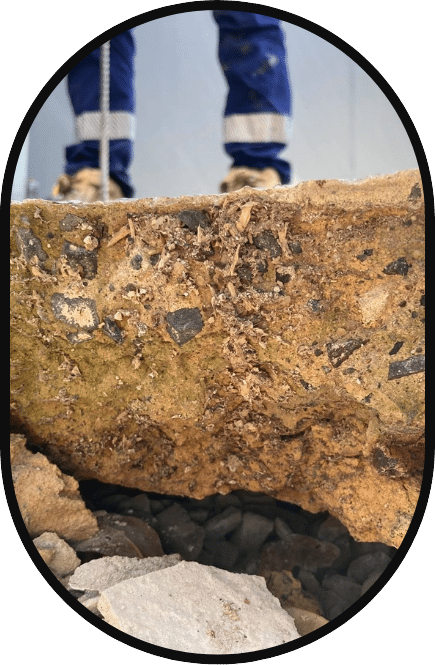

Infill grouting is an excellent solution when a mine has been abandoned. We inject the grout directly into the void to provide stability. It is particularly useful when dealing with large infrastructure projects. Permeating grouting can improve fissured or granular materials’ water resistance and strength. This requires low-viscosity grout to be injected directly into the ground to penetrate and modify the structure’s materials. It is used in a variety of applications, such as dam sealing.

Our range of grout solutions can address various needs, from deep pours to underwater grout for marine environments like desalination plants and Webb Dock. We also provide fast curing options and high-performance construction grouts for critical applications.